Previously we had mentioned about the need of a pre-condenser to alleviate the load of any given vacuum pump.

Any Vacuum pump will benefit from any accessory that will clean up the incoming vacuum stream. Even liquid ring vacuum pumps will benefit from such a device as the vapor load , when turned into liquid, it will occupy less space in the pipe, thus alleviating the gas load and making the vacuum pump more efficient.

In the case when the liquid ring pump is not provided with such a device between the pump inlet and the point of use , all of this liquid load will have to go thru the vacuum pump itself and exit thru the discharge.

Many liquid ring pump manufacturers see this as an added sales point, and even tho it is technically true- it is seldom expressed the possibility of more sealing fluid being required , or even the possibility of needing even colder sealing fluid to handle this heat loads imposed in the pump.

No vacuum pump is immune to the effects of a flooded inlet pipe. As you may recall from your physics class, liquids are not compressible. If any liquid ring pump finds itself with a flooded inlet pipe or a flooded pump casing- Something will break. This is one of the few certainties in life. I have included below a few pictures for your reference of what will happen if excess of fluids is not kept at bay.

As I said before, do not fall prey to these videos I see every once in a while where someone has a garden hose and is feeding a constant stream of water to a vacuum pump. If you notice closely, the pump is already working at full speed when they add the stream of water. If the water being feed to the pump exceeds the volumetric flowrate of the pump, it will lock up as it can’t handle the load of the incompressible fluid, which in this case is water.

Even liquid ring pumps are susceptible to flooding. The claw pumps can’t handle slugs of water either, and their mechanical seals will suffer enormously if this happens with certain frequency.

Rotary vane pumps are the least friendly of the bunch as the vanes will try to compress the liquid (which by laws of physics can’t happen) and the vanes will flex, bent, snap or a combination of all of them.

Now that I have established this baseline, lets get to how to handle a liquid drain loop from your condenser.

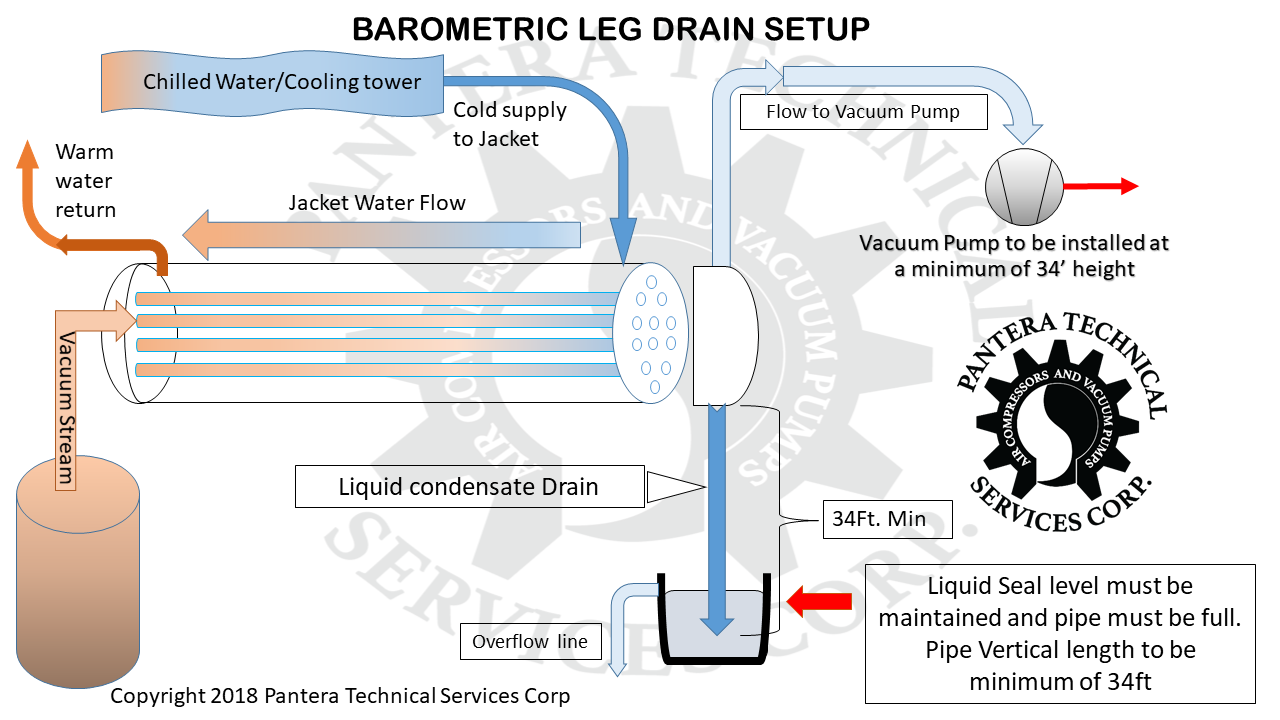

This method is called “Barometric leg” because it relies on the barometric pressure of the jobsite in order to work properly. There are jobsites that can have a shorter total height, but I am of a cautious nature and will give you an example on how to do it at sea level. if you do it otherwise, you do it at your own risk and peril- but then again… I’m only referring to my own experience- Go consult your favorite engineer. They may have a different plan that deviates from my example.

See below drawing before we go at it.

Barometric Leg diagram- Make sure to keep the proper height. Copyright 2018 Pantera Technical Services Corp.

I wanted to illustrate the importance of having AT LEAST 34 feet of vertical height for that drain line.

The vacuum pump also has to be at least 34 feet from the drain level. Notice I have said “from the drain level” instead of ground level as these drains could go into tanks and the pipe stops at the top of the tank, but if the tank is 8 feet tall, you just have to make that up somewhere else. And that place is either at that drain tank, or at the vacuum pump installation location.

The pipe has to remain FULL of liquid at all times. Make arrangements for it.

Remember that the vacuum pump wants to do its job and it will draw air from anywhere that is possible. if the column of the drain fluid is less that 34 feet, the pump may as well overcome that column weight and suck it all into it, causing a major system leak and you will never reach the level of vacuum you desire.

Call or e-mail if you require more information, your site has some specific disadvantages, or just want to discuss your concerns.