A lot has been said about vacuum and router tables. I will try to start from the basics and move up to the more complicated items in a progressive fashion.

First, lets define the possible usage of a router table. These tables are made out of steel , very heavy and sturdy and come in different designs.

Some are “Open Flow Tables” others are of “Pod” design. The open flow tables are always open to the atmosphere and will usually require a bigger vacuum pump. The “Pod” or “Nested” design utilize gasketed areas or “Zones” that can be individually isolated as needed. This design will provide the most efficient use of vacuum, but will require a bigger initial investment as the table requires more materials to begin with (Individual zone valves, gaskets, Checkvalves, etc ,etc ).

Some of these router tables utilize a positive clamping device to secure the main work piece to the table, as to align it properly along the edges. This is called the initial set up. This step involves putting the panel board (usually a 4×8 piece of wood) on the table- but it could also well be a piece of carbon fiber for airplane or boat parts, or a sheet of rigid plastic to be cut to do commercial signage.

The possibilities are numerous as the imagination of the fabricator.

What all of these tables have in common?, despite the usage of a positive clamping system on the edge, is that once the CNC router starts cutting up the work piece, the cut up piece will be freely to move and if its not held down in place it may become a flying projectile, or just move enough to be ruined when the CNC cutting bit moves on to the next piece and this piece gets in the way of the cutting pattern.

Therefore the introduction of vacuum! The vacuum is being used thru the bottom piece of the table, thru perforations in the table bed, it will hold the piece in place until all of the cuts are finished and it is safe to remove them.

Think Safety! Never put your hand on the table while it is in operation. The CNC cutting bit can move anywhere within the work area and cause lethal injury to personnel.

Note the heaviness of the cutting head, and the need of an additional blower on top to handle the sawdust

Longer Table custom made for this customer. Note the multiple access points to hold down the longer work piece

Typical Router Table with 10HP Vacuum Pump – Copyright 2017- Pantera Technical Services Corp

Vacuum pump sizing

Typically there is a rule of thumb of needing about 10CFM per square foot of table works space. This number can move one way or another depending on the the following variables.

- Material Being cut

- Porosity properties of material

- How flat is the material

- How big/small is the final cut piece

- Final weight of the piece

- Cutting head speed

- Cutting tool sharpness at the end of the cut

- Lateral speed/Lateral forces

- Piece deformation upon temperature changes

- Amount and size of shavings created

- Method of shavings disposal or removal from the work area

- Depth of cut/Amount of passes until the piece is actually separated from the main sheet

- Leak Rate added once all the pieces are cut and separated from the main board

- Time required to keep the pieces in place until machine stops safely

- Distance between cutting machine and actual location of pump

- Amount of valves between machine and vacuum pump

These considerations have to be evaluated as a whole when sizing and recommending a vacuum system.

Other considerations to have when specifying the vacuum system:

- Available utilities (Voltage/Amperage service)

- Do you want manual start/stop of the vacuum pump? Or, do you want the vacuum pump to be started from the CNC Router control panel?

- Available Ventilation to cool down the pump

- Distance of pipe to ventilate the pump discharge outside of the work room or building (Hot air need to be evacuated from the room in order to keep the work area comfortable)

- Filtration needed between the pump inlet and table (Do you prefer a clear inlet filter at the table or at the pump?)

- Frequency of cleaning for this filter media (who will be cleaning this filter and how often)

- Actual distance between the vacuum pump inlet and the CNC table itself (needed to calculate pressure loss)

- Pipe/Hose properties that will be used to connect the pump and the table (diameter and roughness)

- Availability of trained personnel to maintain the vacuum pump (Some Vacuum technologies are more labor intensive in the upkeep than others)

Once you have all of these facts, give us a call to give you our take on what Vacuum pump technology and overall setup would be more convenient for you.

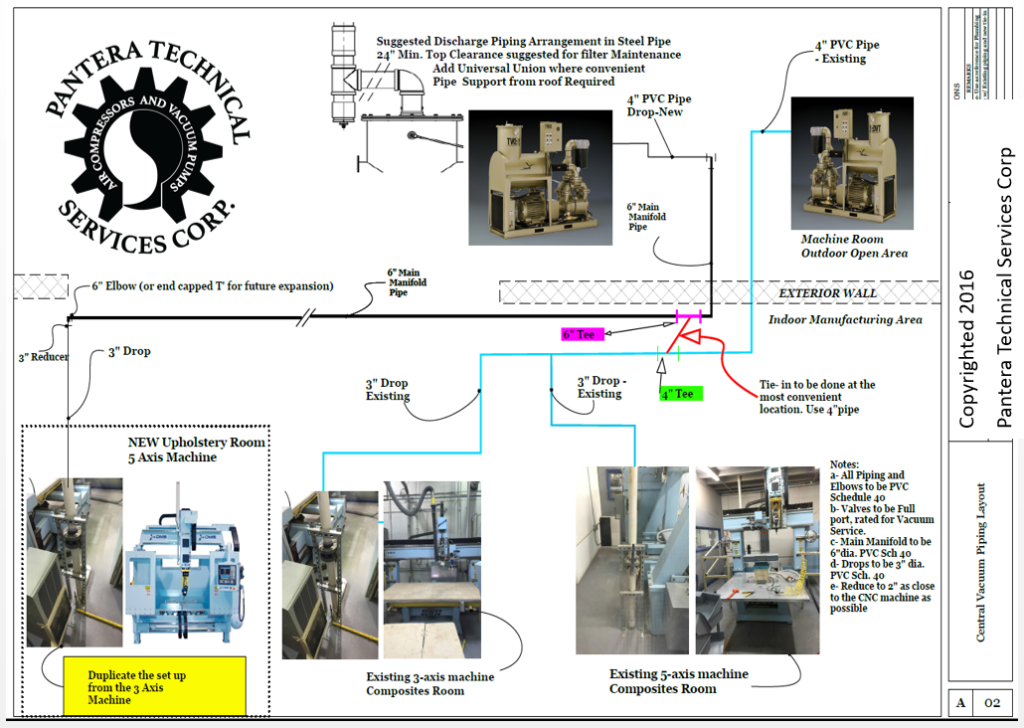

See below a generic layout of a custom job we did for one of our industrial clients that wanted to operate Three CNC Router machines, with only two vacuum pumps. With proper design, it is possible to run multiple CNC Routers with fewer vacuum pumps. For simplicity and illustrative purposes we have omitted many elements (valves, elbows, unions, etc) This is NOT Engineering advice, it is only a sample of our capabilities. Contact us before making any major purchase decisions or commit to specific equipment or layout fabrication.

Custom Central Vacuum system for multiple CNC Machines – Copyright 2016- Pantera Technical Services Corp