Many things have been written about air knives.

The most important thing to consider are:

- Air Velocity

- Slot Size

- Manifold Size

The Air Velocity is determined by the specific application. The velocity required depends on many different factors- each is individual to every customers, but be ready to find out the following:

- Liquid weight, stability and surface tensions

- Possible distance available between air knife to product

- Speed of your production line (Maximun and Minimun)

- Recovery, reuse or disposal method for driven material

- “Splash Zone Area” Define are the limits of the work area

There are a multitude of ways of sizing them, specifying them and most of all- Applying them with more or less efficacy.

I wanted to share something I learned and have applied on my own way since many years ago:

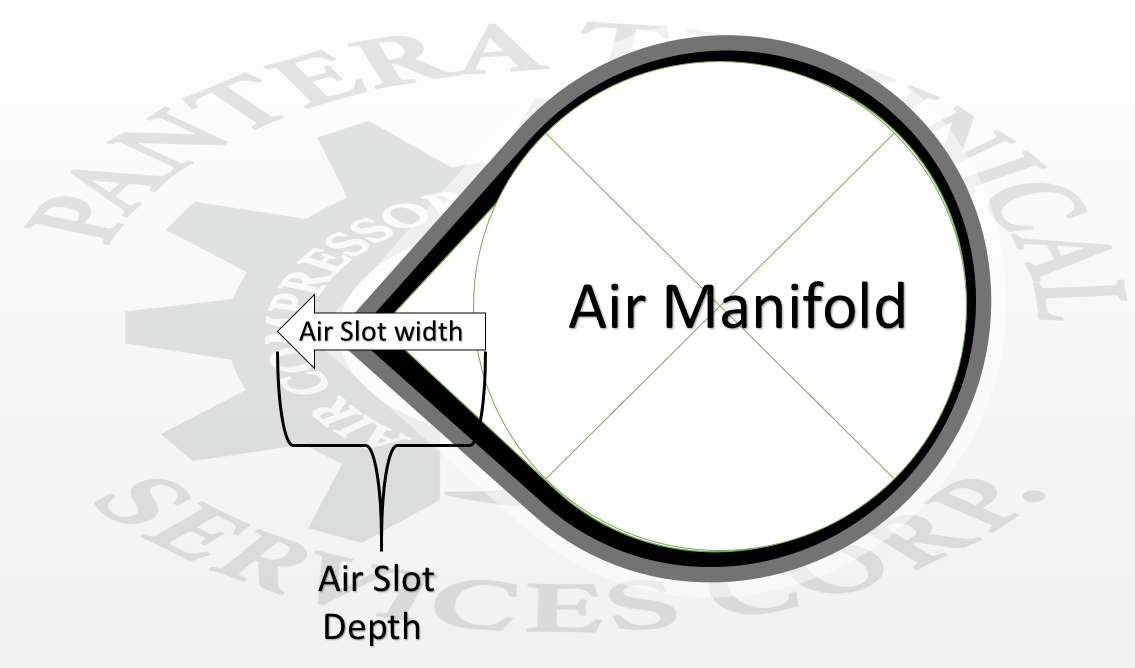

In order to have proper flow on an air knife, the flow slot has to have depth ratio of about 1: 6.

This should help have a stable flow at a constant pressure.

The place in the air knife where the air flows is called “The Slot” .

This “Slot” length, in relation to its thickness (Some people call this thickness, “openness”, etc), should stay within the 1;100 to 1:200 ratio to help out with keeping the flow stable and being able to direct it properly.

These air knives have to be supplied a constant flow of (preferable) Dry clean air. this requirement in the food industry disqualifies piston compressors as they tend to be oil lubricated and the pressure can be of a somewhat pulsating nature. In food applications the air has to comply with very rigid cleaning standards as the air will have contact with food.

The air flow supplied to the air knife comes , usually from a pipe of a bigger than usual diameter. This is to keep turbulence low and flow stable.

This Manifold area is highly recommended to be at least twice of the area of the available slot. Some people use the following equation to determine the minimum manifold I.D to keep the flow turbulence to an acceptable level.

Manifold inside Diameter “D”=2√(area of slot/π)

We will follow up with air quality guidelines and different set ups to obtain the various grades of air cleanliness required for food, laboratory, healthcare and general industrial applications.